Thermal deburring is a highly specialized process used to remove burrs—small, unwanted ridges or imperfections—formed on metal parts during machining or manufacturing processes like die-casting, milling, drilling, or stamping. These burrs, while often tiny, can affect the functionality, safety, and aesthetics of components, making their removal essential, especially in industries where precision is critical, such as automotive, aerospace, and industrial manufacturing.

At its core, thermal deburring uses controlled combustion to eliminate these burrs. The process operates by introducing a carefully regulated mixture of fuel and oxygen into a sealed chamber that contains the metal parts. Once ignited, this mixture generates an intense, short burst of heat—usually reaching temperatures of several thousand degrees Celsius. The heat instantly vaporizes the burrs and excess material from the surface and edges of the part, without damaging or altering the integrity of the underlying component.

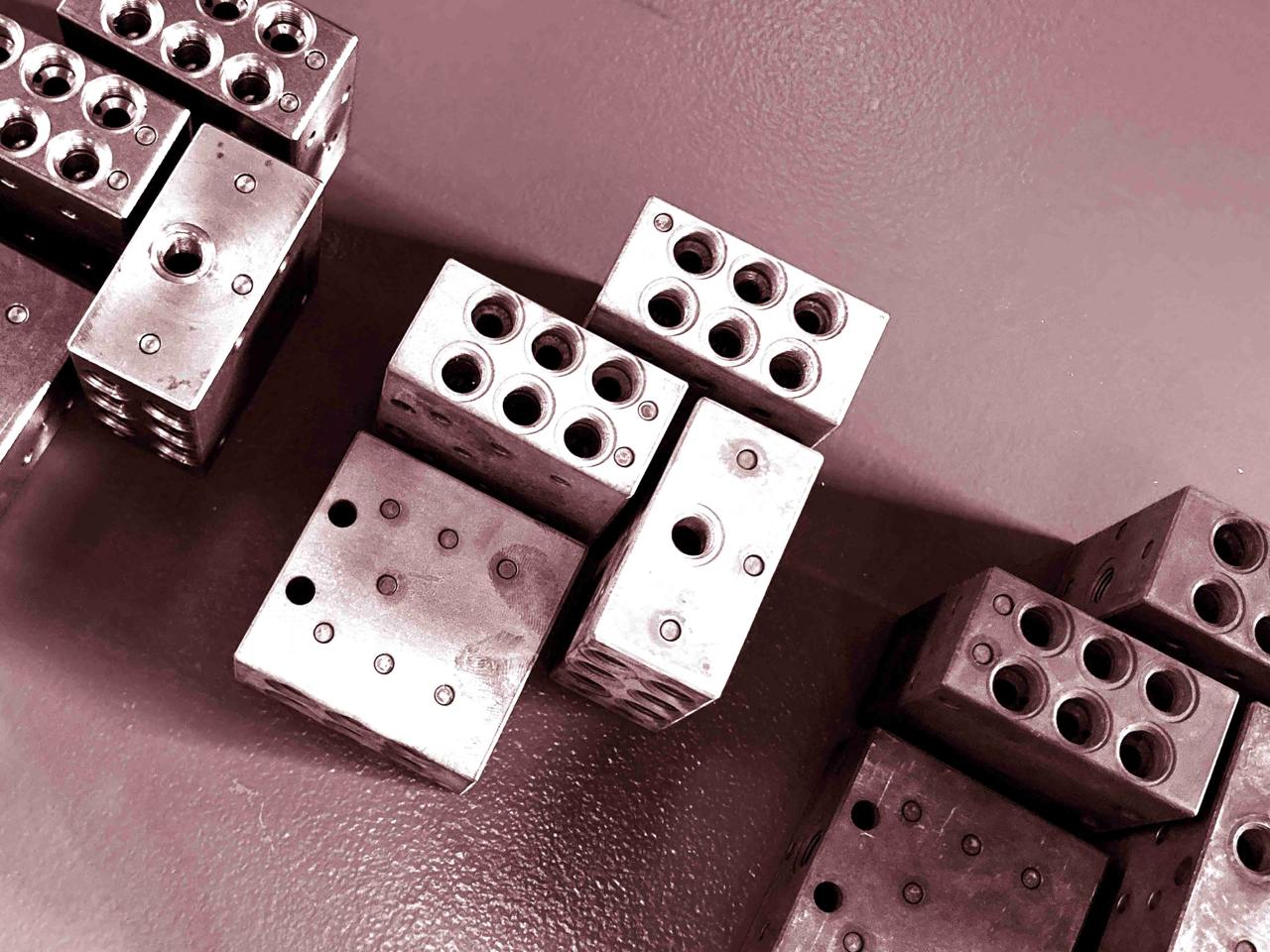

Unlike traditional deburring methods, such as manual filing, grinding, or chemical treatments, thermal deburring is particularly effective for intricate, complex parts with hard-to-reach areas. This makes it ideal for components with internal cavities, small holes, or fine edges where precision and cleanliness are paramount. The controlled combustion process allows for uniform burr removal across every part, ensuring consistency and high quality, even for high-volume production.

The success of thermal deburring lies in the selective nature of the heat application. Because burrs have a higher surface area relative to their size, they oxidize and burn off faster than the surrounding material, leaving the main part untouched. This precision ensures that even the most delicate or complex geometries remain intact and perfectly shaped after the burr removal process.

In modern manufacturing, thermal deburring plays a crucial role in enhancing product performance, increasing safety, and streamlining production efficiency. From engine components in the automotive industry to safety-critical parts in aerospace, the process ensures that finished products meet the highest standards of quality, reliability, and safety.

While many traditional deburring methods can be time-consuming, labor-intensive, and less effective in removing burrs from complex parts, thermal deburring offers a fast, efficient, and highly automated solution. It’s particularly valuable in high-volume production environments where consistency and speed are essential for maintaining tight production schedules and minimizing downtime.